Lower completion

This refers to the portion of the well across the production or injection zone. The well designer has many tools and options available to design the lower completion according to the conditions of the reservoir. Typically, the lower completion is set across the productive zone using a liner hanger system, which anchors the lower completion to the production casing string.

Completion components

The upper completion refers to all components from the bottom of the production tubing upwards. Proper design of this "completion string" is essential to ensure the well can flow properly given the reservoir conditions and to permit any operations as are deemed necessary for enhancing production and safety.

Wellhead

This is the pressure containing equipment at the surface of the well where casing strings are suspended and the blowout preventer or Christmas tree is connected.

Christmas Tree

This is the main assembly of valves that controls flow from the well to the process plant (or the other way round for injection wells) and allows access for chemical squeezes and well interventions.

Tubing hanger

This is the component, which sits on top of the wellhead and serves as the main support for the production tubing.

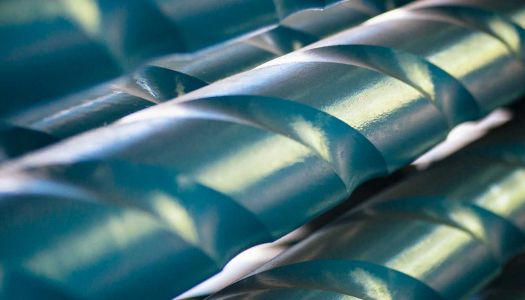

Production tubing

Production tubing is the main conduit for transporting hydrocarbons from the reservoir to surface (or injection material the other way). It runs from the tubing hanger at the top of the wellhead down to a point generally just above the top of the production zone.